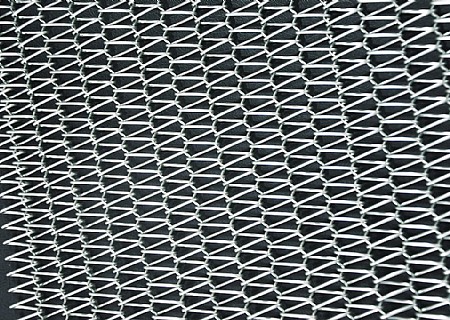

The smooth, flat surface of this conveyor belt offers the best product support without marking

· Less stretch and camber

· Less product marking

· Improved tracking

· Increased product support

· Smoother, flatter surface

Initial belt stretch and camber (distortion) are virtually eliminated because the Balanced Belt-curve spiral has no surplus wire to distort or elongate. The thick, oval spiral of standard round wire belts has a weak shape that is all excess wire. Under tension, it bends and stretches beyond its original pitch length, causing distortion.

Balanced Belt-curve’s smooth, flat surface offers the best product support with no telltale belt marks. Even before the Flat Seat spiral is formed, its round wire is flattened in a rolling mill. It is then formed into a flat, oval spiral. Computerized machines guarantee that each spiral is formed with a precise flatness that is uniformly parallel. Ordinary belts have spirals formed from round wire, and products conveyed on these belts ride unsteadily on the peaks of these spirals, resulting in product markings.

The design of a spiral’s hinge area is also critical to a belt’s life. Ordinary spirals have a rounded hinge area with a point-to-point contact with the cross rod. This point-to-point contact causes excessive wear of the belt’s rods and spirals. The loose fit of the cross rod in the spiral allows continuous rubbing of metal against metal. In contrast, the Flat Seat hinge is designed with a flat, broad contact area. Each spiral hinge is accurately matched and precisely seated to its cross rod to prevent continuous rubbing of metal to metal. This precise match reduces camber and increases belt life.

Flat Seat metal belts are available in a wide range of alloys. contact us to discuss selecting the one that is best for your application.

Key industries: Building Products, Electronics, Food Processing

Key applications: Baking, Cooking, Curing, Dewatering, Drying and Forming, Drying Printed Circuit Boards, Hermetic Sealing, Infeeds and Exits, Thick Film Firing, Transfers, Washing

Oven Balanced Belt-curve

The Oven Balanced Belt-curve is an advancement of the Flat Seat design. It provides ultra-thin, ultra-smooth, vibration-free conveyance. These belts are preferred for drying, curing and baking for several reasons: their strength and durability give a longer belt life; product and belt vibration are eliminated; no product marking; better tracking and they are easily spliced.

Round Balanced Belt-curve

Round Balanced Belt-curve are the best of both worlds. The wire is round on the outside and flat on the inside, allowing for improved tracking and reduced belt stretch while still maintaining the product marking achieved with traditional round wire belts. Balanced Belt-curve are commonly used in the snack food industry.