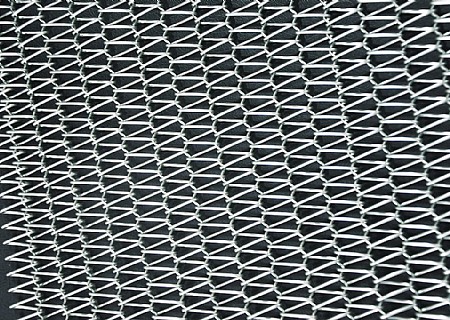

The most universal belt on the market, balanced belts is ideal for almost any product, in almost any environment.

· 25% more carrying surface

· Greater belt stability

· Truer tracking

balanced belts construction makes a Cambridge woven wire metal mesh belt the nearest thing yet to a universal belt! With its flat, thin spirals that deliver 25% more carrying surface than other flattened wire belts, a balanced belt is ideal for virtually any loose or containerized product in applications such as ceramic coating, glass annealing, fiberglass curing, and baking.

balanced belts is calendared only on the top surface of the spiral, maintaining full curvature on lower surface to better fit the crimp seat. A more secure fit eliminates lateral shifting and vibrations, enabling the belt to carry heavier loads. Accurate seating of the diagonally crimped rod also maximizes bearing area and stability. Reduced spiral movement improves tracking.

balanced belts wire is precisely shaped to provide the widest flat area possible on top, without increasing the width of the wire beyond that of conventional spirals. This yields a 25% increase in the conveying area with no loss of open area.

Available in a variety of rugged metals, these belts can handle on-belt processing of light and heavy loads, wet or dry, caustic or acid, from -100°F to +2,200°F. The extra surface area improves drive pulley contact, thereby reducing belt slippage, surging and vibration.

With its nearly perfect interface between the angled crimp seat and the diagonal angle of the spiral, a firmer, more stable seating is achieved. Better seating maximizes the bearing area and minimizes spiral movement for better tracking. By design, balanced belt matches perfectly the angle of the diagonal crimp with the inner curvature of the spiral for low-stress hinging, which assures longer belt life. It also results in approximately 60% less “wear-in” after a new belt is installed. (That so-called “wear-in” is actually a poorly designed belt wearing out as it stretches, seeking seating position.) Flat, thin spirals reduce belt weight, maximize drive pulley contact, and minimize stretching and distortion. balanced belts start smooth and last far longer.

Key industries: Baking, Glass

Key applications:Baking, Ceramic Coating, Fiberglass Curing, Glass Annealing

Baking Belts

For perfectly controlled baking of cookies, biscuits, or cracker products, the ideal choice is a Cambridge compound balanced or balanced belts flat-top balanced weave baking belt. These belts are available in a variety of specifications to adapt to your particular product need.

The compound balanced weave is frequently chosen for baking because of its tightly woven, flat-surface mesh which supports most dough, while permitting gases to escape for proper bottom bake. For many hearth ovens – and wherever a more open mesh can be used –balanced belts are the belts of choice. These belts have been developed to eliminate problems of vibration or pulsation which can occur when using ordinary round-wire belts in long ovens at higher operating speeds. Additional benefits of the balanced belts flat-top belts are their outstanding tracking tendencies and the minimal belt elongation achieved through this design. Both of these benefits are extremely important in baking oven operation. DiaCrimp belts are equally effective for cooling conveyor lines.

Balance belts

JoYa balanced belts have long been the choice of original equipment manufacturers building new units, and of balanced belts operators for replacements. balanced belts are the standard for both annealing and decorating belts in the glass industry. Because the belt is one of the most important components of a systerm proper belt selection will result in more efficient productivity at lower cost to you … and a long productive belt life.

balanced belts must have the correct combination of specifications to meet product requirements for your expected operating conditions (loads, temperatures and time cycles). We combine the very best in belt design and manufacturing technology to produce balanced belts which provide the ultimate in performance and service life. Our balanced belts engineers are at your service to evaluate and propose the correct JoYa belt for your application.

Mesh Selection

JoYa provides a wide selection of mesh specifications to meet product requirements, close mesh weaves for small ware; smooth, flat surfaced weaves for unstable ware; or strong, open mesh weaves for efficient heating and cooling of large pieces. balanced belts are available in Cambriloy 3 (3% chrome), T430 SS, and T316 SS.

Typical balanced belts belt Specifications

|

Mesh Count

|

Wire Size

|

Weight

|

Max. Working Tension*

|

|||

|

In

|

Mm

|

Lbs/SqFt

|

Kgs/SqM

|

Lbs/Ft

|

Kgs/M

|

|

|

DCF-18-16-11-12

|

.120 - .105

|

3.05 - 2.67

|

2.06

|

10.1

|

770

|

1,146

|

|

DCF-30-20-11-12

|

.120 - .105

|

3.05 - 2.67

|

3.5

|

17.1

|

2140

|

3,184

|

|

DCF-30-24-12

|

.105

|

2.67

|

3.44

|

16.8

|

1830

|

2,723

|

|

DCF-30-24-11-12

|

.120 - .105

|

3.05 - 2.67

|

3.94

|

19.2

|

2140

|

3,184

|

|

DCF-30-24-10-12

|

.135 - .105

|

3.43 - 2.67

|

4.25

|

20.8

|

2360

|

3,512

|

|

DCF-30-30-11-12

|

.120 - .105

|

3.05 - 2.67

|

4.56

|

22.3

|

2140

|

3,184

|

|

DCF-36-20-12

|

.105

|

2.67

|

3.63

|

17.7

|

2515

|

3,742

|

|

DCF-36-20-11-12

|

.120 - .105

|

3.05 - 2.67

|

4.25

|

20.8

|

2675

|

3,980

|

|

DCF-36-20-10-12

|

.135 - .105

|

3.43 - 2.67

|

4.50

|

22.0

|

2830

|

4,211

|

|

DCF-36-20-12-14

|

.105 - .080

|

2.67 - 2.03

|

2.13

|

10.4

|

1560

|

2,321

|

|

DCF-48-32-14

|

.080

|

2.03

|

3.25

|

15.9

|

1930

|

2,872

|

*For steel and stainless steel belts operating at temperatures to 600°F. (316°C.) maximum. Maximum working tension is per unit of belt width.