Adaptable conveyor belts for spiral cage systems

· Collapsible for easy cleaning

· Protects product quality and loss

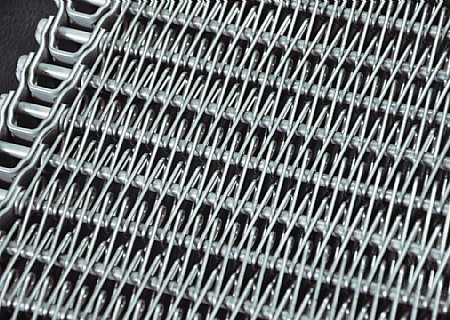

· Available as rods-only or with a mesh overlay

· Metal Grid belts are our most popular application – adaptable spiral cage systems conveyor belts. They’ve proven themselves in spiral cage system applications throughout the world, running smoothly and dependably year after year.

With their positive conveyor sprocket drive, Metal Grid belts provide a smooth, continuous product flow that is gentle with fragile or delicate products. They save money by protecting product quality and reducing waste.

Fully collapsible for easy cleaning, C Metal Grid belts are available in standard (2.2) radius, reduced (1.7) radius, and tight (1.1) radius designs. It can be manufactured with a double pitch overlay, or with plastic filler rods or strips for supporting extremely small products.

Rods-Only Construction

A rods-only construction provides maximum air circulation, making these Metal Grid belts ideal for cookers, proofers and freezers in bakeries. They are also suitable for other applications such as freezing of larger cuts of meat and poultry, and products in trays or packages where minimal product support is required.

Mesh Overlay

When product support or smaller openings are needed, a balanced weave mesh overlay to the conveyor belt is added. Flexibility is maintained, while adapting the Metal Grid belts for a particular application such as freezing soft dough products, beef patties, fish sticks, and other prepared products.

Key industries: Food Processing

Key applications:Cooker belts, Proofer belt, Freezer belt

Standard Radius Specifications

|

Belt Pitch:

|

¾" or 1" (19.1 mm or 25.4 mm)

|

|

Links:

|

¾" pitch standard duty or heavy duty, 1" pitch standard duty or heavy duty.

|

|

Conveyor Belt Width Range:

|

12" to 48" (305mm to 1,219 mm overall) … contact us for other available widths.

|

|

Conveyor Belt Turning Radius:

|

2.2 x belt width (nominal) … special links also available for oversized radii.

|

|

Materials:

|

T-304 stainless steel throughout – with spring-tempered mesh … rods and mesh also available in T-316 stainless steel or high carbon steel … mesh overlays also available in annealed stainless steel.

|

|

Mesh Overlay:

|

Standard mesh overlays available in 14 – 18 gauge mesh wire sizes … specifications are available to fit a variety of product and applications needs, such as open meshes for airflow or tighter meshes for product support.

|

|

Special Constructions:

|

Standard side plates available for ¾" or 1" pitch.

|

Reduced Radius Specifications*

|

Belt Pitch:

|

1" (25.4 mm) nominal

|

|

Belt Turning Radius:

|

1.7 to 2.2 x belt width (nominal inside turning radius)

|

|

Special Constructions:

|

Integral side plates/links available for product retention.

|

*Sprockets are available in stainless steel or carbon steel. **Available in UHMW and stainless steel.

Tight Radius Spiral Cage Belts

Metal Grid Tight Radius belts are available in Standard Duty and Heavy Duty configurations. With a tight turning radius of 1.1 x the belt width, these belts help you achieve maximum product throughput with a minimal footprint.

Tight Radius Specifications - Standard Duty*

|

Belt Pitch:

|

¾" (19.1 mm)

|

|

Belt Width Range:

|

12" to 48" (305 mm x 1,219 mm) … wider widths available depending on application.

|

|

Belt Turning Radius:

|

1.1 to 1.7 x belt width (nominal inside turning radius when tension-bearing links are located in the center of the belt). Contact us for applications involving other turn radii.

|

|

Drive Sprockets:

|

Located on the belt’s inner and center links only.

|

|

Special Constructions:

|

Integral side plate/links available for outer belt edge only.

|

Tight Radius Specifications - Heavy Duty

|

Belt Pitch:

|

1" (25.4 mm)

|

|

Links:

|

Inner: standard collapsible 1" pitch – 1/2” x .105” (12.7 mm x 2.7 mm)

Center: heavy duty non-collapsing 1" pitch – 7/16” x .105” (11.1 mm x 2.7 mm) Outer: standard collapsible 1.33” pitch – 1/2” x .105” (12.7 mm x 2.7 mm) |

|

Belt Turning Radius:

|

Nominal inside turning radius is 1.1 x belt width

|

|

Effective Belt Carrying Surface:

|

4.0” (101.6 mm) less than the overall belt width

|

|

Belt Width Range:

|

12” to 48” (305 mm to 1,219 mm)

|

|

Mesh Overlay:

|

Standard mesh overlays available in 14 – 18 gauge mesh wire sizes … specifications are available to fit a variety of product and applications needs, such as open meshes for airflow or tighter meshes for product support.

|

|

Special Constructions:

|

Only standard construction currently available

|

|

Sprockets:

|

Uses standard sprockets for 1" pitch Cam-Grid belts (18E and 23E only)

Drive sprockets are located only on the inner and center links of this belt |

|

Tension Limits:

|

Heavy duty link 500 lbs. (226.8 kg) straight run 250 lbs. (113.4 kg) turn or spiral

|

|

Heavy duty links are located in the center load-bearing section of the belt, not on the outer edge

|

Tension Limits for Cam-Grid® Metal Conveyor Belts

|

Type of Belt

|

Edge Construction

|

Total Allowable Tension

|

|||

|

Straight Running Application

|

Turn or Spiral Application

|

||||

|

Lbs

|

Kg

|

Lbs

|

Kg

|

||

|

Standard Radius

|

|||||

|

3/4” Pitch or 1” Pitch

|

Standard Duty Link

|

200

|

90.7

|

100

|

45.4

|

|

3/4” Heavy Duty Link (a)

|

200

|

90.7

|

150

|

68.1

|

|

|

1” Heavy Duty Link

|

300

|

136.1

|

150

|

68.1

|

|

|

Reduced Radius

|

|||||

|

1” Pitch

|

Standard Duty Link

|

200

|

90.7

|

100

|

45.4

|

|

Heavy Duty Link

|

200

|

90.7

|

150

|

68.1

|

|

|

Tight Radius

|

|||||

|

3/4” Pitch

|

Heavy Duty Link (b)

|

200

|

90.7

|

150

|

68.1

|

|

1" Pitch

|

1.33 Heavy Duty Link

|

500

|

226.8

|

250

|

113.4

|

(a) 3/4” Heavy Duty link is non-collapsing and is used only on outside edge of the conveyor belt.

(b) Heavy Duty Links are located in the center load-bearing section of the belt, not on the outer edge.

(b) Heavy Duty Links are located in the center load-bearing section of the belt, not on the outer edge.

Metal Grid Belting Sprockets

|

No. Teeth/Sprocket Designation

|

Pitch Dia.

|

Bottom Dia.

|

Hub Length

|

Bore Size

|

Sprocket Thickness

|

Approx. Wt.

|

||||||

|

In

|

Mm

|

In

|

Mm

|

In

|

Mm

|

In

|

In

|

Mm

|

Lbs

|

Kg

|

||

|

Cam-Grid® Sprockets for 3/4” Pitch Belts

|

||||||||||||

|

12T*

|

2.898

|

73.6

|

2.43

|

61.7

|

1.0

|

25.4

|

3/4 or 1.0

|

1.0

|

25.4

|

1.2

|

0.54

|

|

|

25T**

|

5.938

|

150.8

|

5.50

|

139.7

|

1.5

|

38.1

|

1 - 4

|

1.5

|

38.1

|

2.0

|

0.91

|

|

|

Cam-Grid® Sprockets for 1” Pitch Belts

|

||||||||||||

|

9T*

|

3.172

|

80.6

|

2.625

|

66.7

|

1.0

|

25.4

|

3/4 or 1.0

|

1.0

|

25.4

|

1.3

|

0.59

|

|

|

13E**

|

4.410

|

112.0

|

3.850

|

097.8

|

2.0

|

50.8

|

1.0 - 3.0

|

2.0

|

50.8

|

0.7

|

0.31

|

|

|

18E**

|

6.117

|

155.4

|

5.617

|

142.7

|

2.0

|

50.8

|

1.0 - 4.0

|

2.0

|

50.8

|

1.6

|

0.74

|

|

|

23E**

|

7.875

|

200.0

|

7.368

|

187.1

|

2.0

|

50.8

|

1.0 - 4.0

|

2.0

|

50.8

|

2.9

|

1.31

|

|

Standard Radius Spiral Cage Belts

The turning radius of a Metal Grid belt is determined by the ability of the links to nest on the inside edge of the turn and by the width of the metal conveyor belt. Since the slot length determines the amount of nesting and is a fixed dimension, the minimum turning radius becomes a factor of belt width. For a standard radius Metal Grid belt, the nominal inside belt radius is 2.2 x the belt width.